Home > Products > Segregator Buckets

Segregator Buckets

On-site screening is a cost effective and environmentally friendly solution to an increasingly familiar problem. The Anross Auto-Segregator Bucket is an extremely efficient way to carry out this task and has many advantages over similar products.

Applications

- Construction sites

- Recycling & Waste Transfer Stations

- Demolition Sites

- Quarrying

- Land Reinstatement

- Horticultural

Features & Benefits

- Fully automatic operation, using the hydraulic breaker circuit

- Dual width gaps - allowing production of alternative sizes of output material

- Self cleaning action

- Lubricated and shielded drive system

- Manufactured from Hardox steel for high strength and wear resistance

- Low maintenance

- Interchangeable mounting brackets - allows for use on multiple excavators

- Designed and manufactured in the United Kingdom

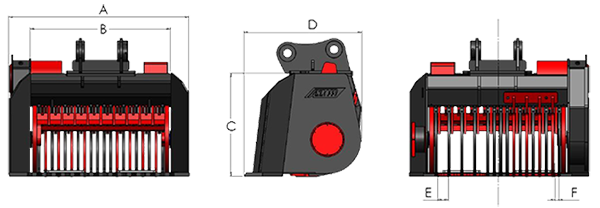

| Auto-Segregator Model Reference | AS80 | AS150 | AS200 |

| Excavator Weight (tonnes) | 5 - 9 | 8 - 15 | 13 - 21 |

| Operating Weight including Mounting Bracket (kgs) (approx) | 580 | 1250 | 1500 |

| Screening Gap Rib Removed - E (mm) Rib Fitted - F (mm) |

62 25 |

80 30 |

100 35 |

| Throughput * (cubic metres/hour) Rib Removed Rib Fitted |

16 - 30 8 - 15 |

30 - 60 15 - 30 |

40 - 80 20 - 40 |

| External Width- A (mm) | 1120 | 1470 | 1700 |

| Internal Width - B (mm) | 780 | 1120 | 1330 |

| Height - C (mm) | 760 | 900 | 970 |

| Depth - D (mm) | 850 | 1050 | 1120 |

| Loading Capacity (cubic metre SAE) | 0.31 | 0.6 | 0.85 |

| Oil Flow (min/max) (LPM) | 75 - 95 | 80 - 100 | 100 - 110 |

| Excavator Supply Line Pressure (bar) | 210 | ||

* Throughput rates are dependant upon the materials being screened. The figures quoted are typical of those achieved in service and are supplied for guidance purposes only.